Linerless Barcode Label: Revolutionizing Business Efficiency

The modern business world is characterized by constant improvement and adaptation to new technologies. One of the remarkable innovations that have gained traction recently is the linerless barcode label. This sophisticated product is reshaping how businesses approach labeling, inventory management, and overall operational efficiency. In this comprehensive article, we will explore what linerless barcode labels are, their advantages over traditional labels, applications in various industries, and how they can be a game-changer for companies like Omega Brand, which specializes in printing services, electronics, and computers.

Understanding Linerless Barcode Labels

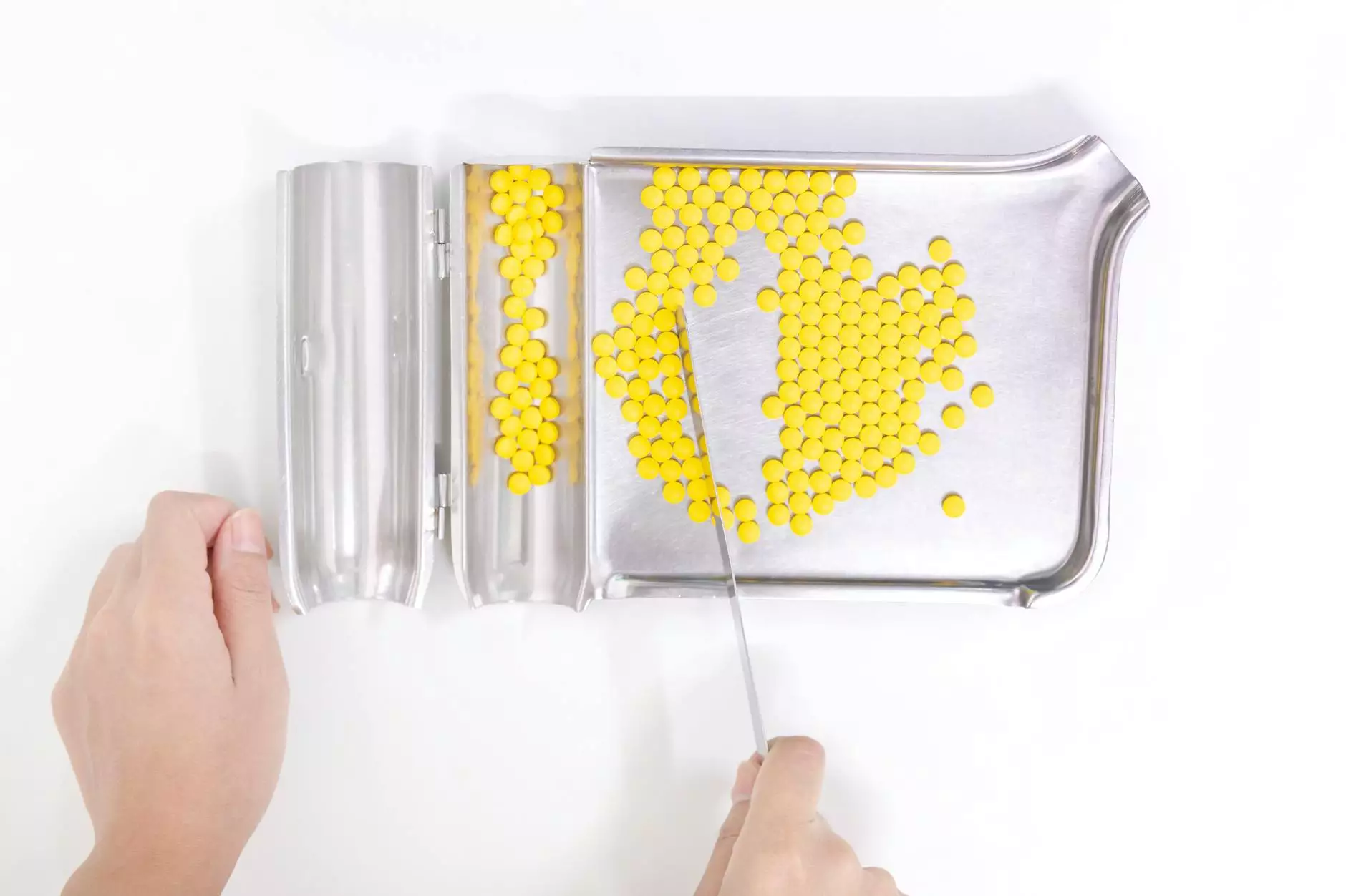

A linerless barcode label is a type of adhesive label that does not utilize a backing liner, which is typically associated with conventional pressure-sensitive labels. Instead, these labels come on a roll, adjacent to one another, allowing them to be peeled off easily without the need for a disposable liner. This innovation leads to numerous benefits that contribute to both environmental sustainability and economic efficiency.

Key Advantages of Linerless Barcode Labels

Utilizing linerless barcode labels presents several advantages that can significantly enhance business operations. Below are the key benefits:

- Reduced Waste: One of the most significant advantages of linerless labels is the reduction of waste associated with traditional label backing. Without a liner, businesses can contribute to a more sustainable environment.

- Cost-Effectiveness: Linerless labels can be more economical in the long run. By minimizing material waste and optimizing label size, companies can save on both printing and shipping costs.

- Increased Efficiency: The design of linerless labels allows for quicker application, which streamlines labeling processes. This is particularly beneficial in high-volume environments where speed is essential.

- Flexible Sizes and Shapes: Linerless labels can be printed in various sizes and shapes, catering to diverse business needs and offering greater flexibility in product labeling.

- Durability: These labels often feature robust materials that withstand various conditions, ensuring that the printed barcodes remain scannable in any environment.

- Enhanced Aesthetic Appeal: The absence of a liner can result in a cleaner and more professional-looking product, which is crucial for brands that hold a premium in the market.

Applications of Linerless Barcode Labels

Linerless barcode labels showcase versatility, finding applications in numerous industries. Below are some sectors that benefit significantly from these labels:

1. Retail

In the retail industry, efficient barcode labeling is essential for inventory management and point-of-sale transactions. Linerless labels allow for quick labeling of products while reducing the amount of waste generated. Furthermore, they facilitate faster checkout processes by offering easily scannable barcodes.

2. Logistics and Warehousing

For logistics companies, efficient handling is crucial. Linerless barcode labels can enhance package tracking and streamline sorting processes within warehouses. The reduced application time and improved scannability can lead to lower operational costs and improved accuracy in inventory management.

3. Manufacturing

In manufacturing, clear labeling of products, parts, and components is vital for efficient assembly lines. Linerless labels ensure that products are labeled quickly and accurately, decreasing the likelihood of errors and bolstering overall production efficiency.

4. Food Industry

The food industry demands labels that adhere securely and remain legible under various conditions. Linerless barcode labels meet these needs by providing durable and moisture-resistant options, essential for tracking food products from production to distribution.

Choosing the Right Linerless Label Solution

When selecting a linerless barcode label, it is crucial to consider several factors that ensure compatibility with your business needs:

1. Adhesive Quality

The adhesive used on the linerless label plays a pivotal role in its performance. Ensure that the adhesive suits the surfaces you’ll be applying the labels to, whether they are plastic, metal, or other materials.

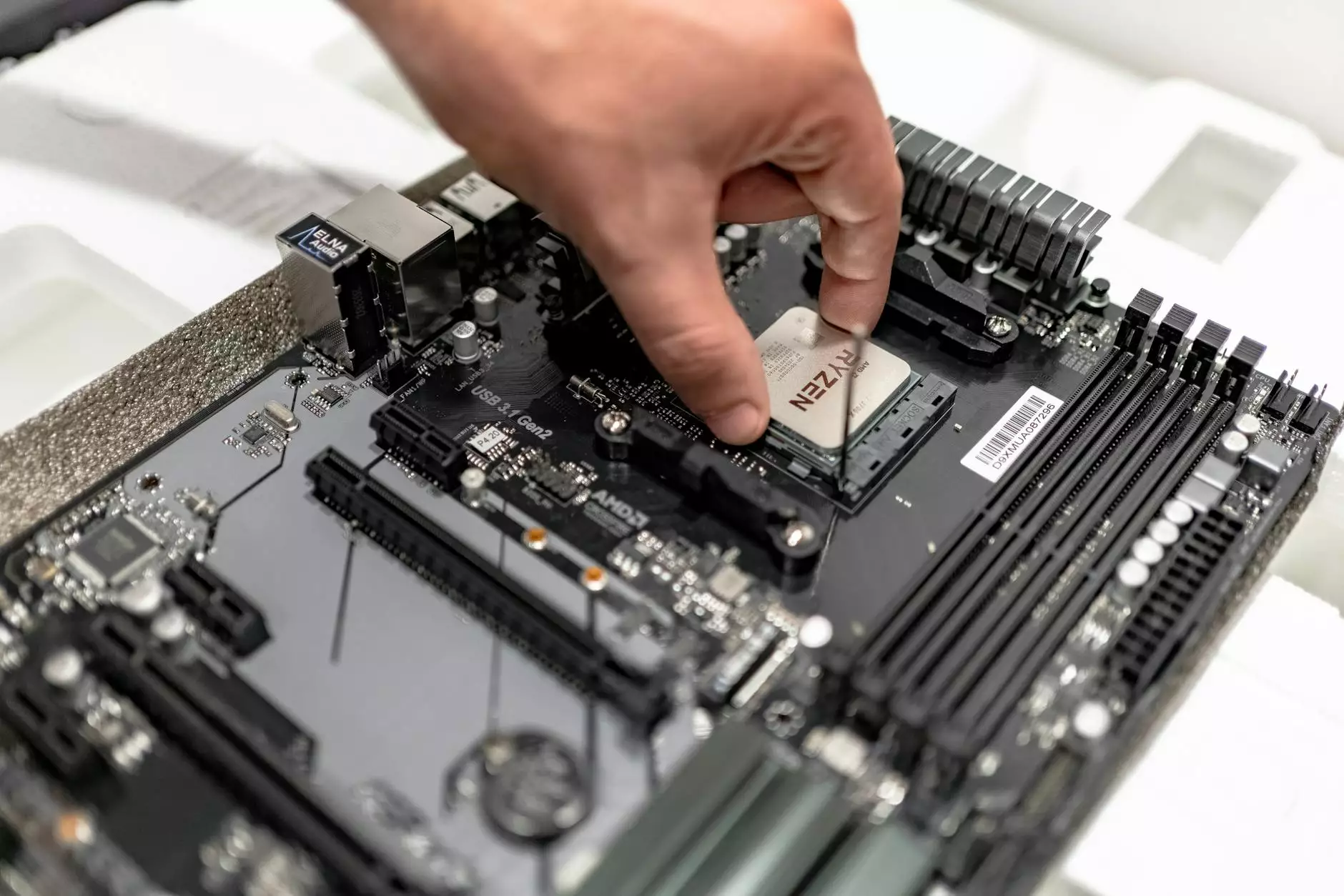

2. Printer Compatibility

Not all printers are equipped to handle linerless labels. Verify that your existing printing equipment can accommodate these labels, or consider investing in a compatible label printer.

3. Environmental Considerations

Explore eco-friendly linerless label options that utilize renewable materials and sustainable manufacturing processes to enhance your company’s sustainability efforts.

4. Regulatory Compliance

Especially in industries like food and pharmaceuticals, it is essential that your labeling complies with local and international regulations, ensuring labels meet all necessary requirements.

Best Practices for Implementing Linerless Barcode Labels

To maximize the effectiveness of linerless barcode labels, consider the following best practices:

- Staff Training: Ensure that your staff is adequately trained on applying and scanning linerless labels to prevent mishaps and maintain efficiency.

- Regular Maintenance: Keep your printing equipment and scanners in good condition to ensure optimal performance with linerless labels.

- Trial and Error: Start with a small batch of linerless labels to test their applications across various products before wide-scale adoption.

- Feedback and Improvement: Gather feedback from staff regarding label performance and make improvements based on their experiences. Continuous optimization will lead to better outcomes over time.

Conclusion

In conclusion, the rise of the linerless barcode label is a reflection of how innovative labeling solutions can significantly enhance business operations across various industries. By reducing waste, minimizing costs, and improving efficiency, linerless labels present a sustainable choice for companies like Omega Brand in the realms of printing services, electronics, and computers. As businesses continue to evolve and adapt to changing market demands, adopting advanced labeling solutions such as linerless labels is essential for maintaining a competitive edge.

Start exploring the potential of linerless barcode labels today, and transform your business operations for the better.