The Growing Business Potential of 3D Printing: Emphasizing S65 Technology

In today's fast-evolving technological world, businesses are constantly seeking innovative methods to enhance their operations and improve efficiency. 3D printing has emerged as one of the most revolutionary advancements across various sectors, including manufacturing, healthcare, and even construction. At the forefront of this advancement is the S65 technology, which is transforming the 3D printing landscape. In this in-depth article, we will explore the remarkable benefits of S65 technology and how it can propel businesses towards unprecedented growth and success.

Understanding 3D Printing and S65 Technology

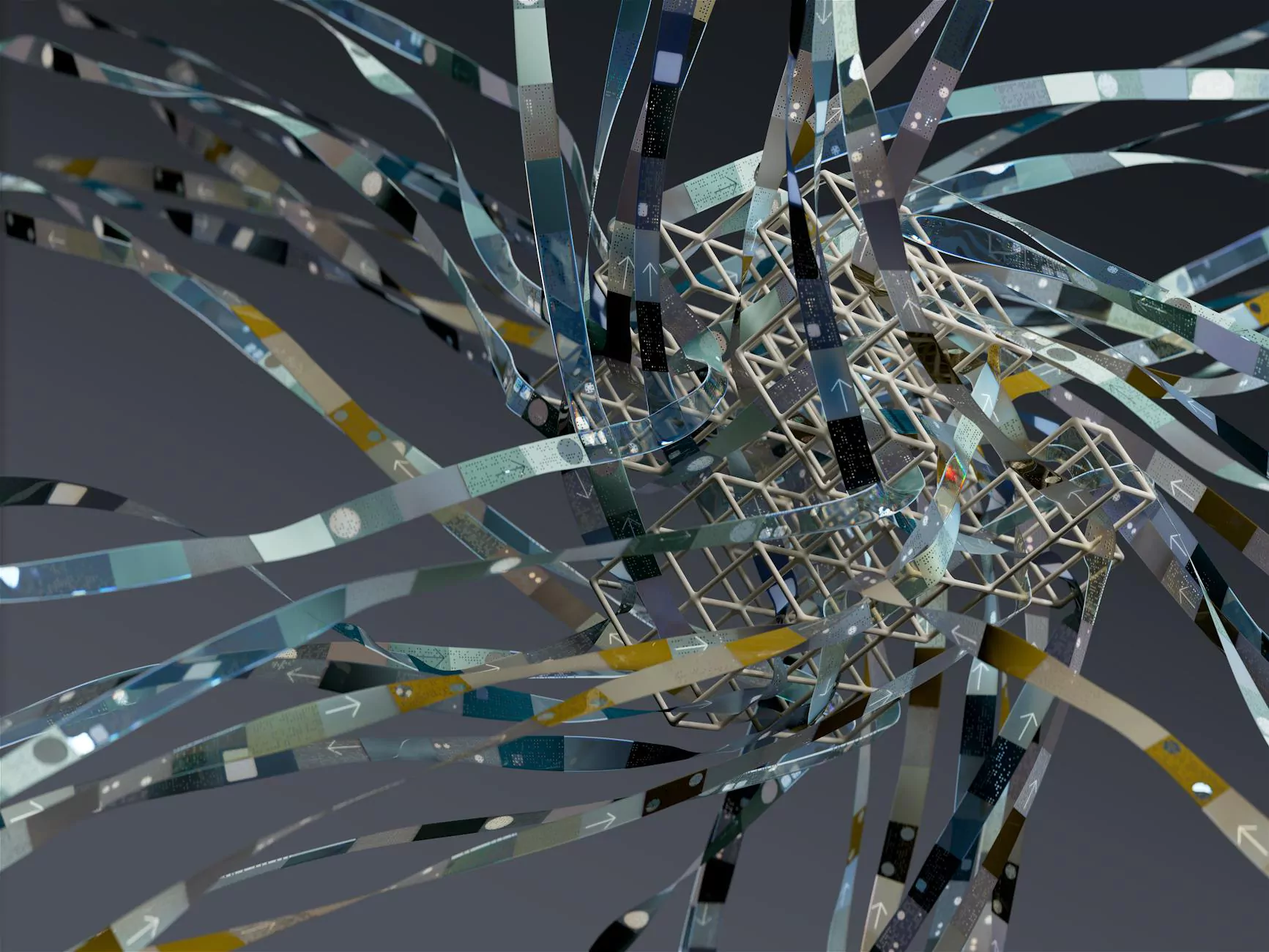

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. This technology enables the production of complex shapes and designs that were previously impossible or cost-prohibitive to achieve. With the development of various printing materials and techniques, the application of 3D printing has expanded significantly, allowing businesses to streamline their production processes.

The S65 technology stands out among other printing methods. It refers to an advanced category of 3D printing, characterized by its speed, precision, and versatility. The S65 systems are known for their capability to handle a wide range of materials while ensuring high-quality output. This technology has gained particular attention in industries where customization and rapid prototyping are essential.

The Advantages of S65 Technology in Business

Implementing S65 technology within a business offers numerous advantages that can enhance productivity and overall performance. Here are some of the key benefits:

- Speed: S65 technology significantly reduces production timelines. Businesses can manufacture prototypes and end-products in a matter of hours instead of weeks.

- Cost-Effectiveness: With S65 technology, companies can lower overhead costs by minimizing material wastage and reducing the need for extensive labor.

- Customization: Businesses can easily create customized products tailored to specific customer needs without the extensive changes associated with traditional manufacturing.

- Complex Designs: S65 3D printing permits intricate designs that are often impossible to achieve with conventional methods.

- Material Versatility: The technology supports various materials, offering businesses flexibility in their product development processes.

Industry Applications of S65 3D Printing Technology

The application of S65 technology spans several industries, each leveraging its unique capabilities to enhance operations and create value. Here are some notable sectors:

1. Manufacturing

In the manufacturing sector, S65 technology is revolutionizing how companies produce parts and components. With the ability to create complex geometries and reduce lead times, manufacturers can switch to just-in-time production models, drastically reducing inventory costs. Leading companies use S65 technology for creating prototypes and final products, enabling quicker market entry and increased competitiveness.

2. Healthcare

The healthcare industry benefits immensely from S65 technology through the production of customized medical devices, implants, and even bioprinting tissues. Surgeons can use patient-specific models created via S65 technology for pre-surgical planning, leading to improved outcomes and minimized risks.

3. Aerospace and Automotive

In aerospace and automotive industries, the need for lightweight yet strong components is paramount. S65 technology enables the production of high-performance parts with reduced weight, contributing to better fuel efficiency and performance. The use of 3D printing in these sectors also accelerates the design process, making it easier to innovate and experiment with new designs.

4. Architecture and Construction

The architectural field has embraced S65 technology for creating intricate models and components. Furthermore, the potential for large-scale 3D printing in construction is gaining traction, with companies exploring possibilities for 3D-printed buildings. This method promises significant reductions in material waste and construction time, thereby allowing for sustainable and efficient building practices.

Transforming Business Models with S65 Technology

Adopting S65 technology not only enhances existing manufacturing processes but also has the potential to transform entire business models. Here are some key changes that can occur:

- Shift Towards On-Demand Manufacturing: Companies can reduce the risk associated with overproduction and warehousing by only producing items as required.

- Enhanced Collaboration: With 3D printing, designers and engineers can collaborate more effectively, making it easier to iterate designs and prototypes in real-time.

- Environmental Sustainability: Reduced material waste and energy consumption during production can contribute to a smaller carbon footprint for companies utilizing S65 technology.

- Increased Market Responsiveness: The rapid prototyping capabilities allow businesses to quickly adapt to market demands and introduce new products faster.

Challenges and Considerations

While the benefits of S65 technology are significant, businesses should also be aware of the challenges that come with its adoption. These include:

- Initial Investment: The upfront costs associated with high-quality 3D printers and materials can be a barrier for some businesses.

- Training and Expertise: Workers will require training to effectively operate S65 printers and utilize the technology for design and production.

- Quality Control: Maintaining consistent quality and adhering to industry standards can be more complex compared to traditional manufacturing processes.

Future Trends in 3D Printing and S65 Technology

The future of 3D printing, especially with advancements like S65 technology, looks promising. Emerging trends indicate:

- Integration with AI and Machine Learning: The combination of these technologies will lead to smarter manufacturing processes, enhancing precision and reducing waste.

- Expansion in Material Choices: As research continues, more materials may become available for S65 printing, including metals and biodegradable plastics, broadening its application.

- Increased Adoption in Various Industries: As more businesses recognize the benefits, we can expect to see an uptick in the adoption of S65 technology across a broader range of sectors.

Conclusion

In conclusion, S65 technology represents a significant leap forward in the realm of 3D printing. Its capacity to streamline operations, reduce costs, and facilitate innovation positions it as a powerful asset for businesses aiming to stay competitive in today’s fast-paced environment. As industries continue to adapt and evolve, embracing technologies like S65 will be crucial for sustainable growth and success in the future. Organizations willing to invest in this technology will not only enhance their operational efficiencies but also pave the way for a more innovative and resilient business model.

The journey into the realm of additive manufacturing is just beginning, and infotron.com.tr is at the forefront of this technological evolution. Explore the endless possibilities that S65 and 3D printing can bring to your business and become part of the future today.