Understanding Non Return Valve Drainage: Essential Insights for Effective Security Systems

Non return valve drainage systems are crucial components in modern security and drainage solutions. Designed to prevent backflow, they play a significant role in protecting various infrastructures, especially in flood-prone areas. This article delves deep into the mechanics, benefits, applications, and maintenance strategies related to non return valve drainage, providing an in-depth resource for businesses looking to enhance their security systems.

The Importance of Non Return Valve Drainage in Security Systems

The use of non return valves in drainage systems is essential for safeguarding properties from potential water damage, especially during heavy rain or floods. These valves ensure that once the water has passed through, it cannot flow back, thereby reducing the risk of flooding inside premises.

How Non Return Valves Function

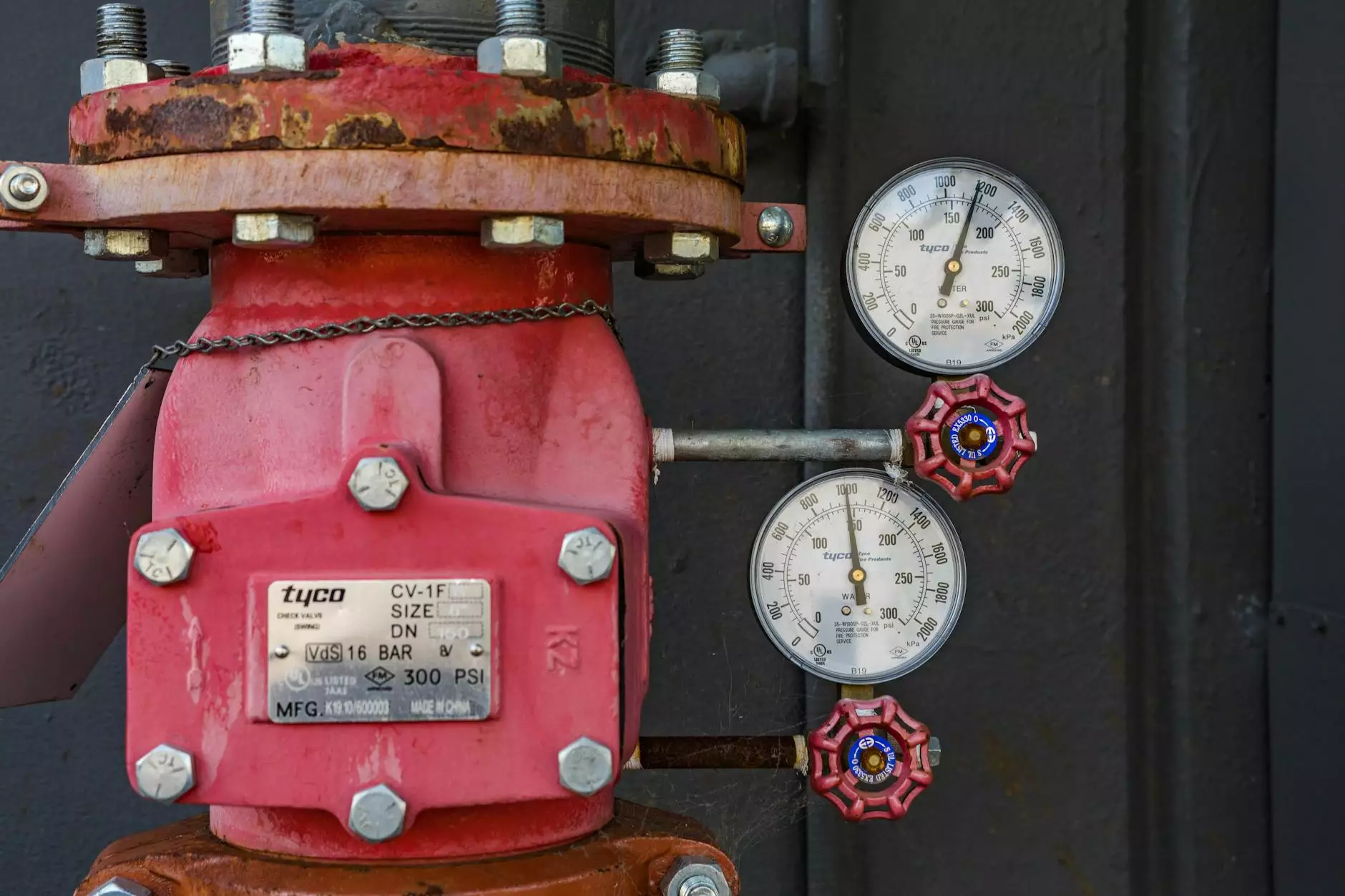

Non return valves, also known as check valves, allow water to flow in one direction only. Here’s how they work effectively:

- Directional Flow: The valve permits water to flow toward the drainage system while automatically closing when water attempts to flow back.

- Pressure Regulation: Through built-in mechanisms, they can handle changes in pressure, maintaining stability in the drainage system.

- Prevention of Contaminants: By stopping backflow, these valves prevent contaminants from re-entering clean water sources.

Benefits of Non Return Valve Drainage

Utilizing non return valve drainage systems in your security setup can bring about a multitude of benefits:

1. Flood Protection

Arguably the most crucial benefit, these valves are pivotal in protecting properties from flooding caused by heavy rainfall. By preventing backflow, they ensure that excess water is directed away from vital infrastructures.

2. Enhanced Reliability

Non return valves add reliability to drainage systems. Their robust designs allow for consistent performance under varying conditions, making them a dependable option for businesses.

3. Cost Efficiency

Investing in non return valve drainage can lead to significant savings in the long run. By mitigating water damage, businesses can avoid costly repairs and replacements, ensuring that expenditures are kept to a minimum.

4. Environmental Protection

By preventing the backflow of potentially contaminated water, these valves contribute to environmental sustainability. Protecting waterways from pollutants is not only beneficial for ecosystems but also complies with regulatory standards.

Applications of Non Return Valve Drainage in Various Industries

The utility of non return valve drainage systems extends across multiple industries. Here are several applications:

1. Residential Properties

Homeowners can significantly benefit from installing non return valves in their drainage systems, particularly in areas susceptible to flooding. These systems are instrumental in safeguarding basements and ground-level floors.

2. Commercial Buildings

For businesses, especially those located in high-risk flood zones, incorporating non return valve drainage can protect valuable assets and inventory. It ensures that operations can continue without the threat of water damage.

3. Industrial Facilities

Industries that deal with hazardous materials can incorporate these valves to prevent contamination. Ensuring that spills or leaks do not result in backflow into clean water systems is crucial for environmental safety.

4. Agricultural Operations

Farmers benefit from non return valves in irrigation systems, preventing water from flowing back into reservoirs and causing inefficiencies in water usage.

Choosing the Right Non Return Valve for Your Needs

When implementing a non return valve drainage system, several factors must be considered to ensure optimal performance:

- Valve Type: There are various types of non return valves, including swing, lift, and diaphragm valves, each suited for different applications and conditions.

- Material: The material of the valve should withstand environmental conditions, such as corrosion and pressure variances.

- Size and Flow Capacity: Selecting the appropriate size and flow capacity is vital. A valve too small can restrict flow, while one too large may not effectively prevent backflow.

- Installation Requirements: Proper installation is key to the functionality of non return valves. Ensure that qualified professionals handle installation to avoid costly mistakes.

Maintenance of Non Return Valves

Like any mechanical system, regular maintenance of non return valves is necessary to ensure long-term functionality and prevent failures.

1. Regular Inspections

Conduct routine inspections to check for any signs of wear or corrosion. Early detection of problems can help in prompt repairs or replacements.

2. Cleaning

Debris can accumulate over time, obstructing the flow and potentially causing backflow. Regularly clean the valve and surrounding areas to ensure optimal performance.

3. Replacement of Damaged Valves

If a valve shows significant wear, it is more cost-effective to replace it rather than attempting repairs, which might not yield reliable results.

Conclusion

In conclusion, understanding and implementing non return valve drainage systems is essential for businesses looking to safeguard their properties against water damage. The benefits, applications, and maintenance considerations outlined in this article provide a comprehensive overview for making informed decisions. By choosing the right solutions and ensuring proper maintenance practices, businesses can enhance their security systems, protect their investments, and contribute to environmental sustainability.

For more information and expert guidance on non return valve drainage and other security systems, visit floodgate.ltd.uk today!